What are O-Rings Used For? Discover the Different O-Ring Seal Types and Benefits

Yee Ming Ying Co., Ltd. — Established in 2001, specializing in rubber products and forging of hardware parts. We provide custom mold design, production, and one-stop fulfillment for precision sealing components.

Introduction: Small Parts, Big Impact

In industrial assemblies, compact components often make the biggest difference. O-rings are a prime example: small, circular gaskets that deliver reliable sealing across countless machines and systems. At Yee Ming Ying Co., Ltd., we engineer and produce high-quality O-rings that help our clients improve performance, reduce leaks, and extend service life.

What Is an O-Ring?

An O-ring is a loop-shaped mechanical gasket made from elastomeric materials such as rubber, silicone, nitrile (NBR), or fluorocarbon (e.g., Viton/FKM). When compressed between mating surfaces, the O-ring creates a tight barrier that prevents the escape of liquids or gases.

Key Characteristics

- Simple circular design that seals effectively with minimal space.

- Versatile usage in both static (fixed) and dynamic (moving) applications.

- Material flexibility including EPDM, NBR, NR, CR, Viton (FKM), PU, and silicone to match operating environments.

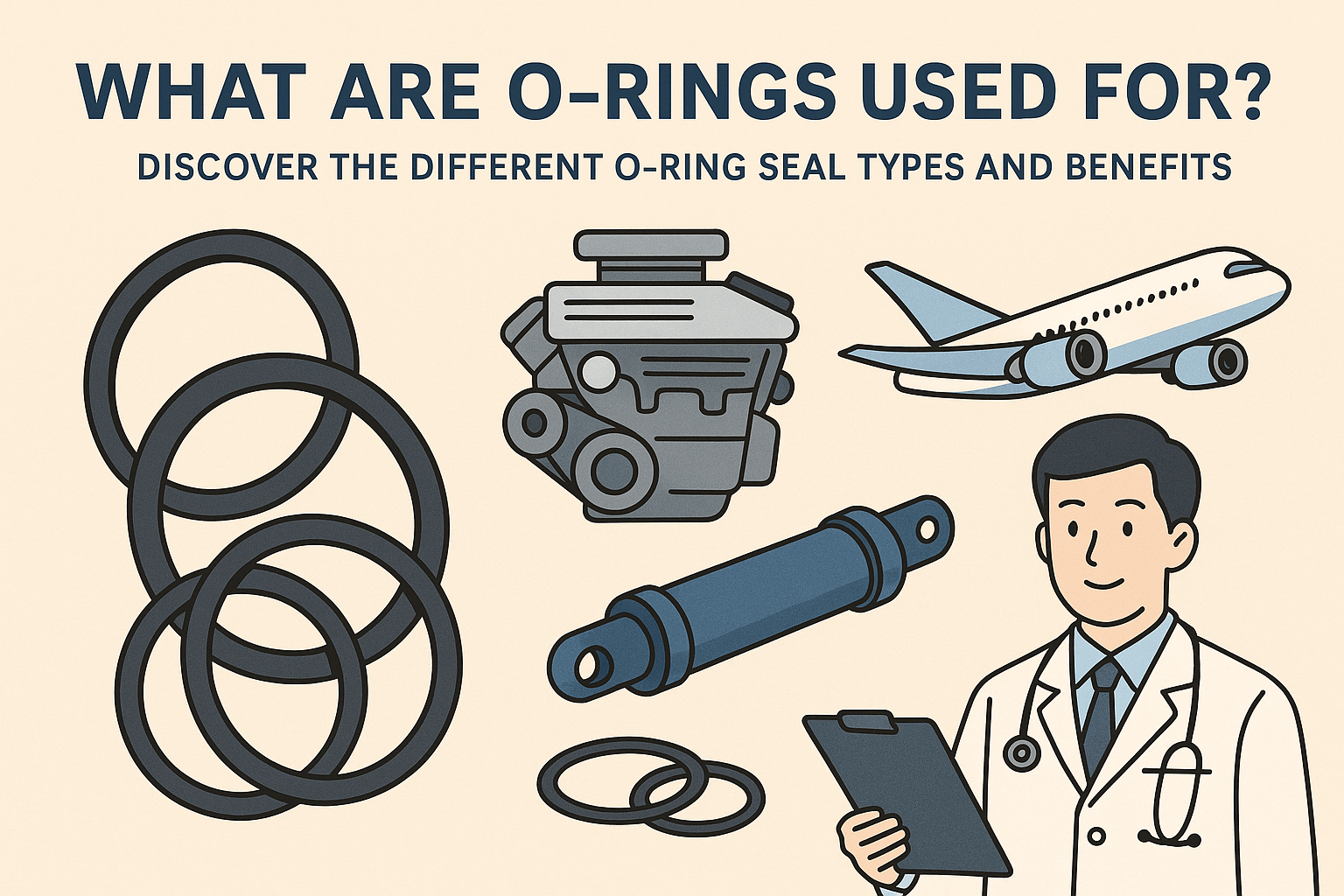

What Are O-Rings Used For?

O-rings are indispensable across industries due to their dependable sealing and ease of installation. Typical applications include:

- Automotive: Engines, fuel systems, transmissions, A/C systems, and braking circuits to maintain pressure and prevent fluid loss.

- Aerospace: Engines, hydraulic systems, and fuel handling where high temperature and pressure resistance are critical.

- Industrial Machinery: Pumps, valves, compressors, and gearboxes that face vibration and pressure fluctuations.

- Electrical & Electronics: Water/dust ingress protection for appliances, instruments, and sealed enclosures.

- Marine & Shipbuilding: Hydraulic systems, hatch covers, and propulsion components exposed to saltwater and mechanical stress.

- Medical & Healthcare: Sterile, biocompatible sealing in pumps, syringes, and diagnostic devices.

O-Ring Seal Types

While the geometry is simple, O-rings are deployed in several sealing modes. Selecting the right O-ring seal type ensures optimal performance and service life.

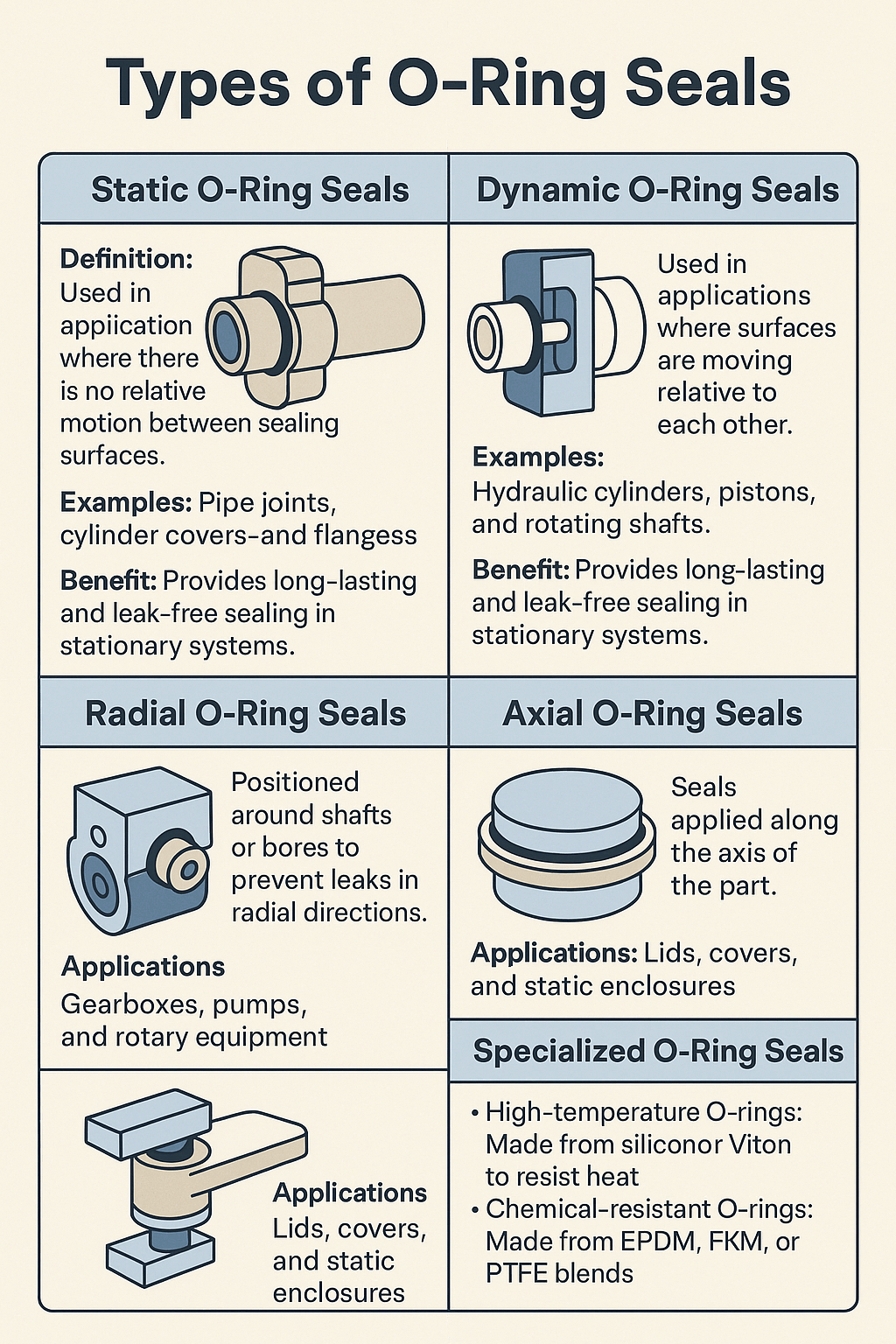

1) Static O-Ring Seals

Definition: Used where there is no relative motion between the sealing surfaces.

Typical uses: Pipe joints, cylinder heads/covers, and flanged connections.

Benefit: Long-lasting, leak-free sealing in stationary interfaces.

2) Dynamic O-Ring Seals

Definition: Used where surfaces move relative to each other (reciprocating or rotating).

Typical uses: Hydraulic/pneumatic cylinders, pistons, and shafts.

Benefit: Formulated to endure friction, wear, and pressure changes.

3) Radial O-Ring Seals

Definition: Seals pressure in the radial direction (around shafts or bores).

Applications: Pumps, gearboxes, and rotary equipment.

4) Axial O-Ring Seals

Definition: Seals along the axis of the components (face-type sealing).

Applications: Lids, covers, end caps, and static housings.

5) Specialized O-Ring Seals

- High-temperature: Silicone or FKM for elevated heat exposure.

- Chemical-resistant: EPDM, FKM, or PTFE-filled blends for aggressive media.

- Food/medical grade: Certified silicone or NBR for hygienic applications.

Key Benefits of O-Rings

- Simple & cost-effective: Economical to produce, quick to install, and easy to replace.

- Reliable sealing: Handles pressure, temperature, and media variations with predictable performance.

- Broad material options: Tailored resistance to oils, fuels, steam, chemicals, and weathering.

- Compact & lightweight: High sealing efficiency with minimal space requirements.

- Cross-industry usability: Suitable for automotive, aerospace, medical, marine, electronics, and general machinery.

Choosing the Right O-Ring Material

Yee Ming Ying Co., Ltd. provides customized O-rings in diversified compounds so each application achieves optimal performance.

| Material | Strengths | Typical Uses |

|---|---|---|

| EPDM | Excellent weather, ozone, and steam resistance | Water/steam systems, outdoor sealing |

| NBR (Nitrile) | Good oil, fuel, and hydraulic fluid resistance | Automotive fuel lines, hydraulic equipment |

| Viton (FKM) | High temperature and chemical resistance | Aerospace, chemical processing, high-heat engines |

| Silicone | Wide temperature range, flexibility, biocompatibility | Medical devices, food processing, electronics |

| PU (Polyurethane) | High abrasion and tear resistance | Dynamic seals, reciprocating motion |

| CR (Neoprene) | Balanced oil, ozone, and aging resistance | General industrial, marine hardware |

| NR (Natural Rubber) | Excellent elasticity and resilience | Shock/vibration damping environments |

Why Choose Yee Ming Ying Co., Ltd. for O-Rings?

- One-stop customization: Professional mold opening, production, and shipment for tailored specs.

- Industry breadth: Proven in automobiles, motorcycles, aerospace transportation, machinery and equipment, ship hardware, electrical appliances, and sports equipment.

- Quality assurance: Rigorous inspection and material traceability to meet demanding standards.

- Engineering support: Material and design guidance to optimize seal life and total cost of ownership.

Conclusion

Understanding what O-rings are used for and the various O-ring seal types is essential to building reliable, efficient systems. With the right material and seal configuration, O-rings provide durable performance in both static and dynamic environments. Yee Ming Ying Co., Ltd. delivers precision-engineered O-rings and end-to-end support to help you specify the ideal solution for your application.